Annual Report 2014

14

Summary of achievements

The CO

2

Capture Sub-Programme has achieved

the followings:

• New class of precipitating absorbents with

good absorption rates, easily dissolved pre-

cipitate and fast CO

2

desorption rate have

been identified. A more simplified process for

precipitating system for CO

2

capture has been

proposed based on the properties of the new

precipitating system. This process have possi-

bilities to utilize waste heat in plants for sol-

vent regeneration. Further this process offers

possibility for higher pressure CO

2

recovery.

• Dynamic test campaign was completed in the

Gløshaugen pilot plant. Dynamic model that

can be implemented in various solvent based

capture pilots has been developed. The dy-

namic model was implemented to represent

the test result from Gløshaugen pilot plants

and also a dynamic model for Tiller pilot plant

was implemented.

• The long-term flux performance of symmetric

hydrogen pre-combustionmembranes has been

tested up to 1500 hours in H

2

and CO

2

contain-

ing atmospheres at 1000C, and the degradation

phenomena have been elucidated by post-char-

acterization of the membrane material.

• A new, analytic mean flame shape model, that

considerably improves present state-of-the-

art approaches for prediction of flashback in

ducts, is developed and validated versus Direct

Numerical Simulation datasets.

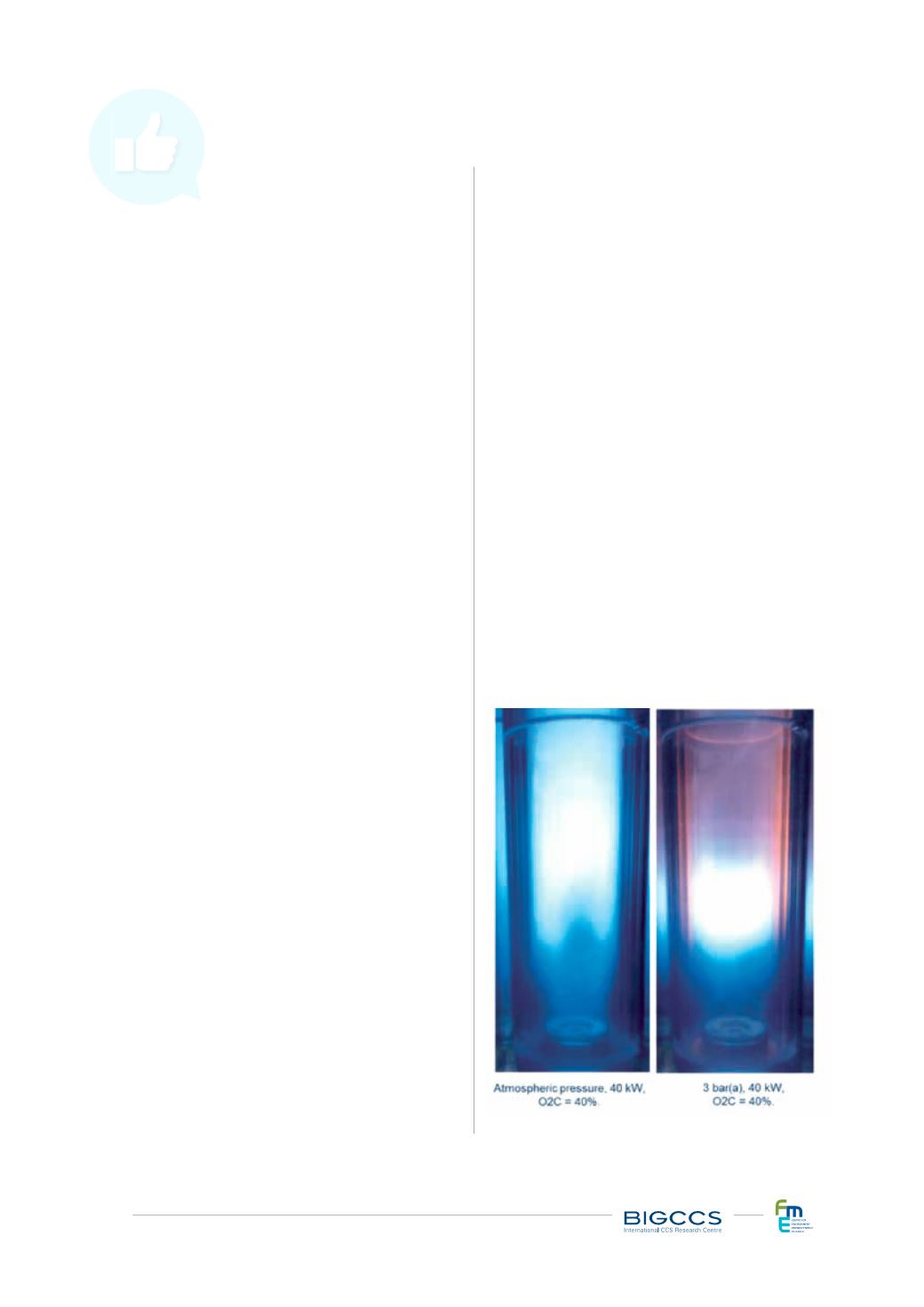

• The technology based on flameless com-

bustion (FLOX®) has been experimentally

demonstrated in high pressure conditions

at DLR and shown to be a good candidate to

achieve Exhaust Gas Recirculation in the flue

gas to be treated in post-combustion capture,

while avoiding combustion stability issues.

• A swirl stabilized burner for semi-closed

oxy-fuel gas turbine application has been tested

under pressure for the first time in the HIPROX

facility. This burner will be used in the demon-

stration oxy-fuel plant to be built through EC-

CSEL infrastructure funding from RCN.

• The 150 kWCLC rig has been installed at Tiller,

and first non-reacting operation has been per-

formed.

• Continuous operation of the 3 kW CLC attri-

tion test rig in Oslo for more than 100 hours

has been achieved, and four new batches of ox-

ygen carriers for CLC has been produced and

tested.

• A new dolomite based material for carbon-

ate looping processes has been found to yield

higher cyclic capacity and less deactivation

than regular dolomite.

• Investigation of the IGCC process with Distri-

buted Fuel Injection (DFI), proves that there is a

potential for efficiency improvement in addition

to resolving the challenges with H

2

combustion.

• Evaluation of an amine-based Novel Generic

Solvent (NGS) to establish an additional bench-

mark for post-combustion CO

2

capture from

Natural Gas Combined Cycles (NGCC) and to

illustrate how adding improvements for amine

capture (new solvent, reduced temperture dif-

ference in reboiler, Exhaust Gas Recirculation)

can yeald a significant reduction in capture

penalty.

• Improvement of a heat- and mass balance

model for Chemical Looping Combustion, sub-

sequently applied for an evaluation of steam

generation in refineries.

Oxy-fuel burner in operation.

(Photo: SINTEF)