Annual Report 2014

16

The most recent achieve-

ment is the installation of

a large test rig of 150 kW

capacity installed at Tiller

during 2014.

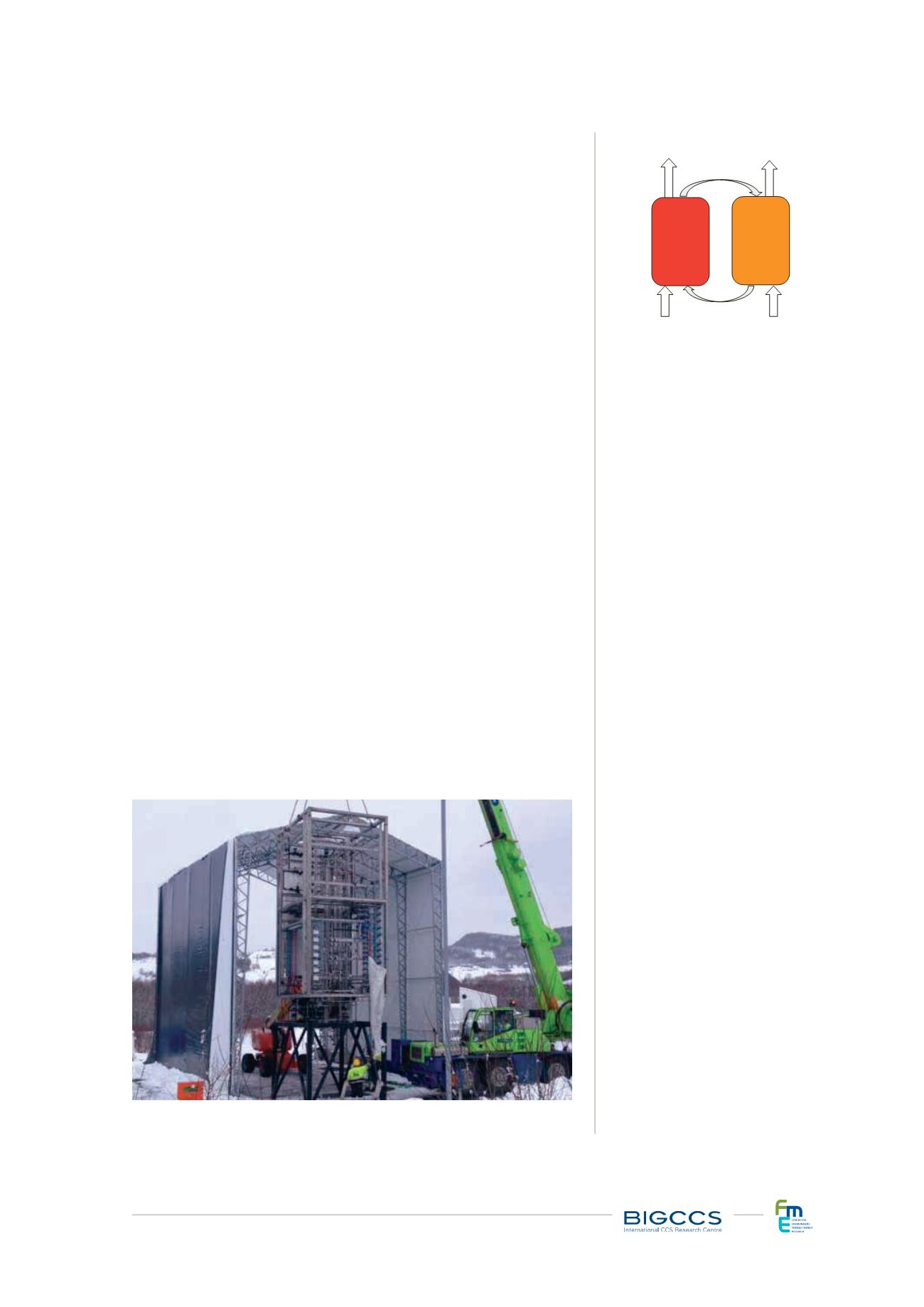

Installation of the 150 kW CLC rig.

(Photo: Øyvind Langørgen)

The clue in CLC is the way the oxygen is produced. The standard

method for oxygen production is by cryogenic distillation of air

at very low temperatures. CLC uses instead that metal particles

can be rapidly oxidized in air at high temperatures, in the order

of 850 – 1000°C. That is, the particles extract oxygen from the air.

The resulting metal oxide particles are then transported to the fuel

where the oxygen is released and used for burning the fuel. There-

after they are transported back in order to continue the “looping”

process as illustrated in the figure. This can be less energy intensive

and costly than standard oxygen production methods.

The main challenges in CLC are development of suitable metal

oxide particles as well as appropriate reactor and control systems

for long time continuously operation. The metal particles must

survive and do the job at high temperatures, they should ideally

extract and release as much oxygen as possible in as short time as

possible (some seconds) and they should not break down into fine

powder, or agglomerate and clog into larger particles. The reactor

and control system must ensure stable operation, high circulation

of particles and full burn-out of fuel.

The most recent achievement is the installation of a large test rig of

150 kW capacity installed at Tiller during 2014. The rig is intended

for gaseous fuels. The reactors are 6 meters high with diameter

of 240 and 160 mm. At this size small scale effects are of minor

importance and the results obtained can more easily be transferred

to even larger test rigs and demos. Preliminary tests have been

done, both at low and high temperatures, but at time being without

fuel gas supply. The first tests with fuel gas supply and real reactive

CLC operation is planned within 2014. The 150 kW rig is so far the

last and largest step in the chain of development and infrastructure

built up within the CLC activity of BIGCCS.

Principle of Chemical Looping

Combustion.

Oxygen

depleted air

CO

2

+ H

2

O

MeO

Me

Exoth.

Endoth.

Exoth.

Fuel

Air

Metal

oxide

reduction

Metal

oxidation