A N N U A L R E P O R T 2 0 1 5

17

Enabling H

2

fueled gas turbines

• A new Direct Numerical Simulations was

completed in early 2015 (figure previous

page), and data analysis has revealed import-

ant aspects of flashback occurring in a stratified (non-homogeneously mixed) reactants

in hydrogen-fired gas turbines. Stratified

combustion is a highly relevant condition to

modern low NOx gas turbine combustors.

• Analysis of a second set of DNS datasets,

representing injection of three IGCC-type

syngas fuels with different degree of carbon

capture (H

2

-N

2

only, CO-lean H

2

-N

2

, CO-rich

H

2

-N

2

), revealed that flame anchoring

characteristics are nearly unaffected by the

specific fuel composition as long as hydrogen

is present in the fuel.

Oxy-fuel technologies

• Oxy-fuel combustion at a scale that is relevant

for actual gas turbines has

been studied using the

HIPROX facility (figure

to the right). The burner

developed at SINTEF has

been tested at thermal

power loads up to 40

kW and 5 bar pressure.

The potential for emis-

sions of unburned CO is

quantified as a function

of parameters such as

pressure, power, oxygen

concentration and excess.

• In order to demonstrate

a gas fired oxy-fuel cycle, DEMOXYT Infra

structure, the commercial 100 kW

e

gas tur-

bine has been delivered and commissioned in

2015, as part of RCN ECCSEL Phase 2 project.

• In the quest for lowering energy penalty

in CCS concepts, the use of Exhaust Gas

Recirculation (EGR) in pre-combustion power

cycles are studied. The potential benefit of the

technique has been published in terms of NOx

emissions from the hydrogen fired gas turbine.

• The scientific output in 2015 has been four

peer-reviewed publications in journals, 3

conference presentations, and the coordination

of a workshop on “DNS for solid fuel flames”.

Looping technologies

• The 150 kW CLC rig has been further

modified and the heat-up of the entire reactor

system to temperatures above 900°C (suitable

for oxygen carrier particles, ilmenite) is

successfully achieved.

• The PhD candidate has developed a numerical

simulation tool for the fluid and particle flows

in the 150 kW CLC reactor. The tool currently

handles both reactors individually, consider-

ing chemical reactions in the reactors.

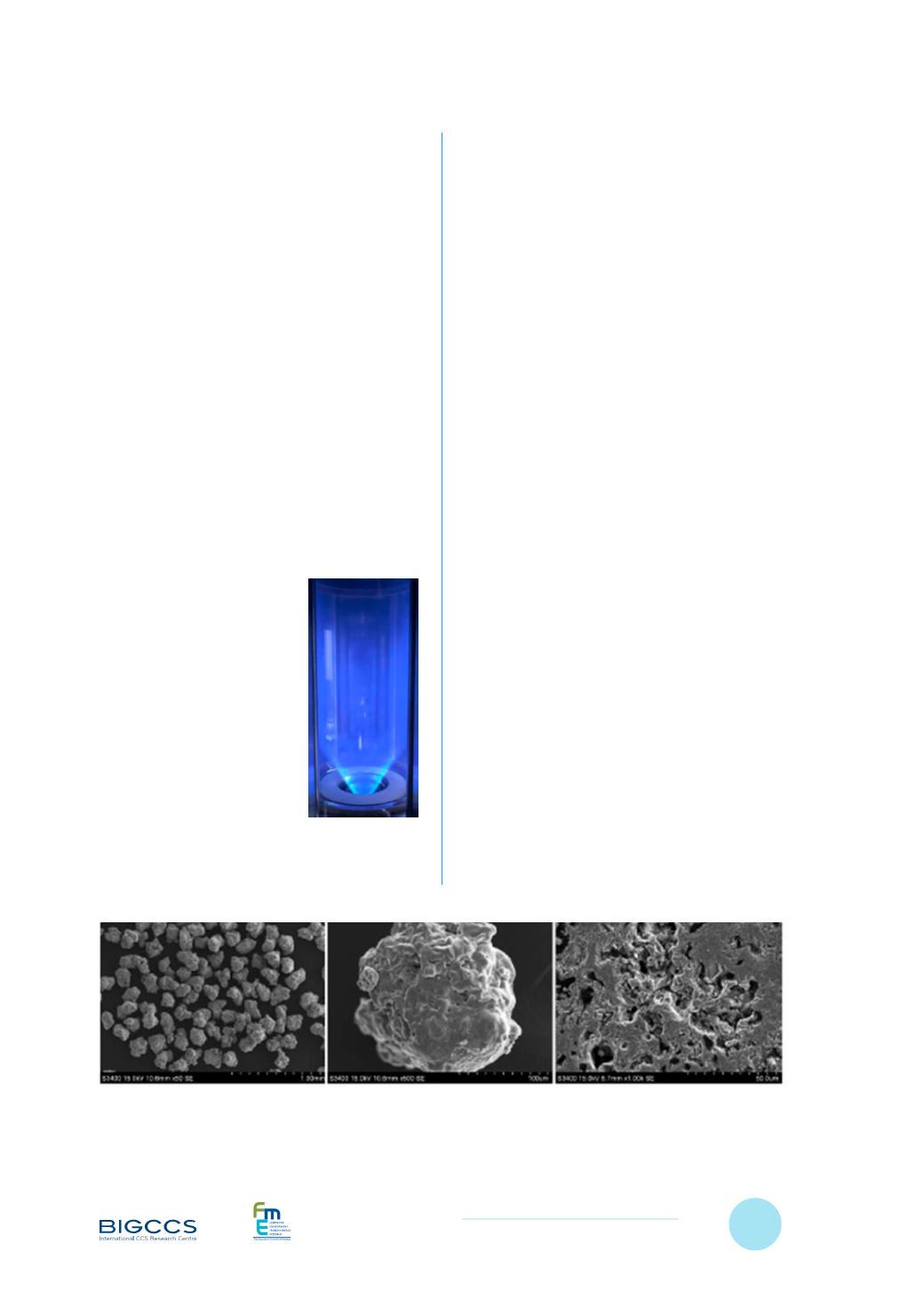

• New durable high capacity oxygen carrier

materials, based on CaMn(Ti)O

3

system

substituted with iron, have been developed.

Three different batches of materials produced

in amounts suitable for the 3 kW hot rig and

by methods that is possible to scale up has

been tested and evaluated (figure below).

• In continuation of the work on High Tempera-

ture CO

2

Sorbent, we have studied the effects

of steam and how this influences the working

capacity of CaO and calcined dolomite (MgO-

Scanning electron micrographs of CaMn(Ti)O3 subsituted with Fe. From left to right: overall view, focus on

one granule, cross-section of a granule.

HIPROX facility