20

SUBPRO Subsea Production and Processing

Modelling and multivariable control of subsea systems

Traditionally, the big and easily available oil fields

offshore producing from a topside processing

plant have already been developed. The oil and

gas industry now focuses on increased oil and gas

recovery from brownfields and on development of

smaller oil and gas greenfields. Subsea process-

ing will be a key factor both for increasing oil and

gas recovery on existing fields and for making new,

smaller oil and gas fields economically feasible.

Subsea processing plants are small compared to

topside processing plants and have fast dynamics

and strong interaction between units. This fast

dynamics poses challenges with transients and

modelling which are important for analysis and

design of online multivariable control and optimi-

zation. The control oriented models need to be fast

and sufficiently accurate to describe the physical

properties of the subsea processing plant. Thus,

the objective of this subproject is to create stand-

ardised models for a complete subsea processing

plant, analyze and improve interacting control

loops and design a multivariable control structure

to utilize the strong interactions and fast dynamics

Project manager and main

PhD supervisor, Prof. Olav

Egeland

PhD candidate, Torstein

Thode Kristoffersen

Co- supervisor, Associate

Prof. Christian Holden

Co-supervisor,

Prof. Sigurd Skogestad

GLCC

Phase splitter

De-liquidizer

in

Q

1

Q

2

Q

3

Q

5

Q

out

liq

Q

,

out

gas

Q

,

1,

liq

h

5,

liq

h

1

p

to handle transients and optimize production, e.g.

linear/nonlinear Model Predictive Control. An

important research objective will be to find the

minimum buffer volume necessary to sufficiently

control the process and handle transients with

multivariable control.

The models to be developed will start from recent

separation technology, (e.g. the CompactSep

separation system developed by Statoil in collab-

oration with Chevron, Petrobras, Total and FMC)

and extend with boosting and cooling, including

actuator dynamics, processing time delay and

transmission of signals and power. An intension

is that the modelling work should result in a

general framework for standardized modelling of

subsea processing plants. A laboratory of several

microcontrollers is to be constructed and run

with various parts of the complete control model

of compact subsea process to study the effect of

increased time delay subsea. During the modelling

work, focus will be given to numerical solutions of

the models for the simulation to be fast enough.

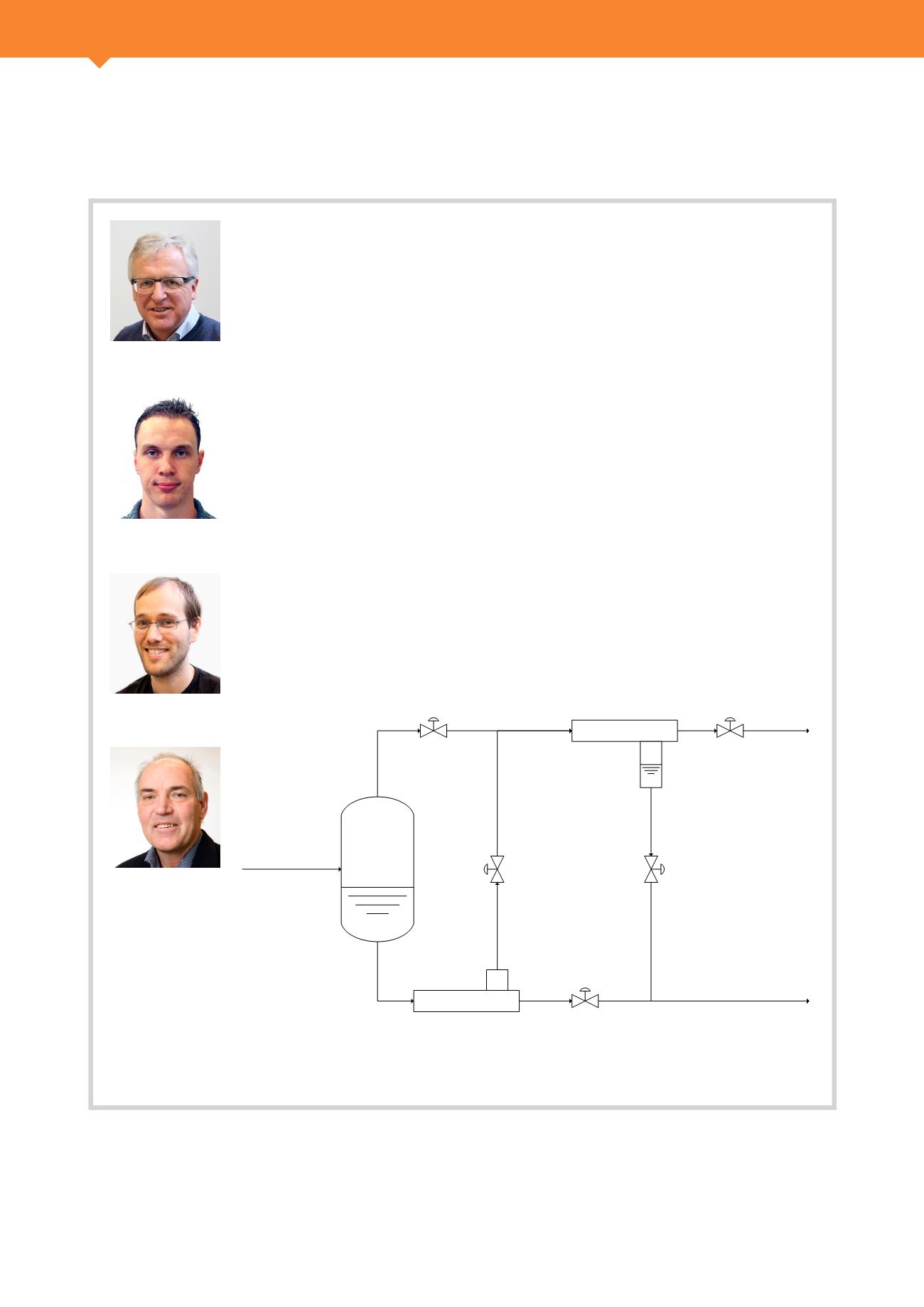

Figure 15. CompactSep, an example of a separation system to be modelled. Patented separation process by

Statoil. Picture from presentation at the 22nd Mediterranean Conference on Control and Automation 2014.