22

SUBPRO Subsea Production and Processing

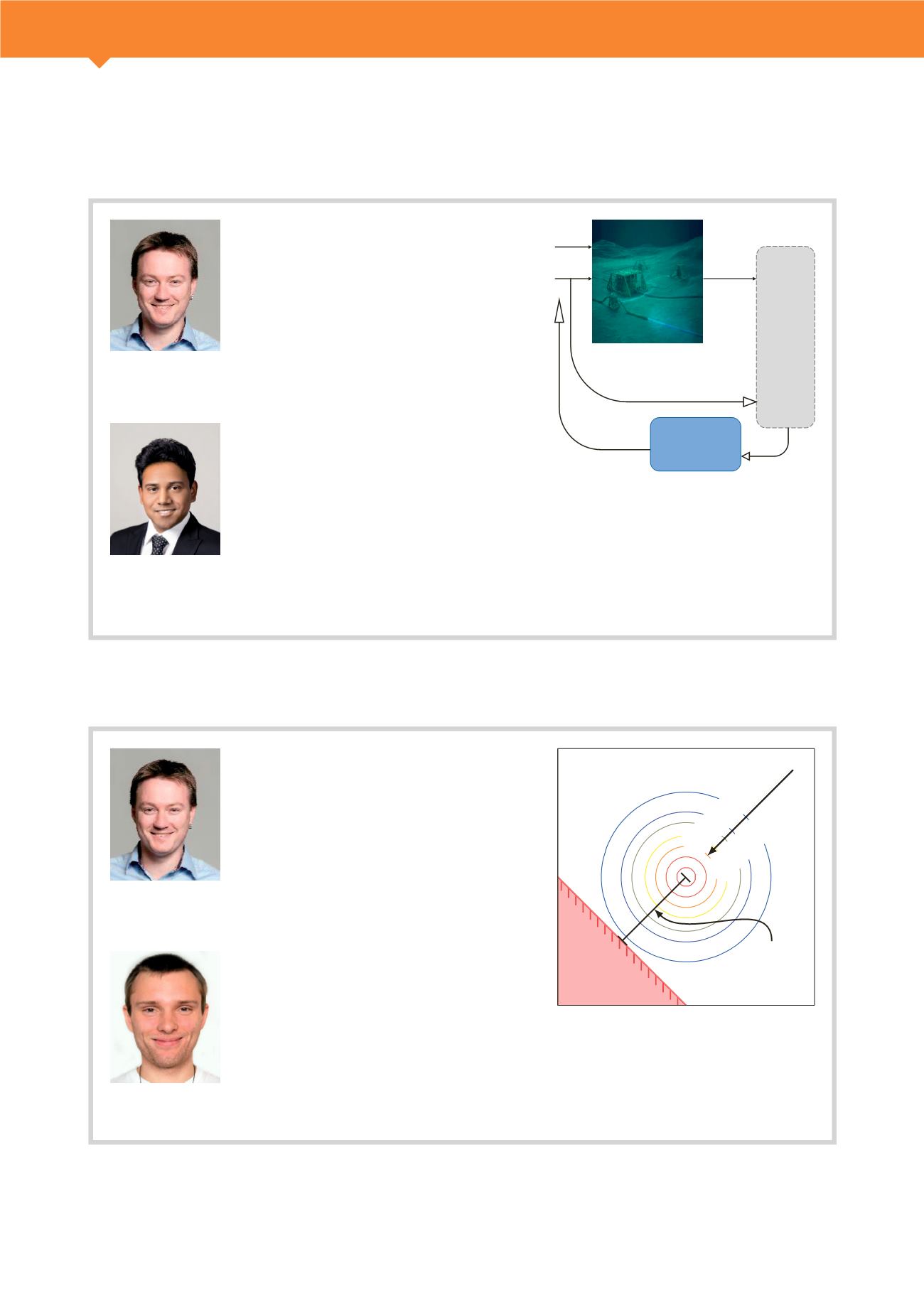

In subsea oil and gas production, unexpected stops

result in the loss of valuable production time.

Additionally, the cost of intervention in the case of

a module breakdown is very high due to the need

for specialized intervention vessels and remotely

operated vehicles (ROV). It is for these reasons

that the equipment is designed and operated in

such a fashion that the chance of failure becomes

marginally small (large back-off from operational

constraints). However, this approach can lead to

very conservative operation.

Our idea is to combine health monitoring and

process control to find the optimal back-off from

the constraints. The goal is to ensure that the

RUL (Remaining useful life) of the equipment

is not exceeded before the next planned main-

tenance stop, while maximizing production. We

will develop computer models and algorithms to

solve this problem.

Control for extending component life

Project manager and PhD

supervisor, Associate

Prof. Johannes Jäschke

PhD student, Adriaen

Verheyleweghen

Failure

Decreasing RUL

Increasing profit

”Back-off”

x

1

x

2

Figure 18. Illustration of constraint back-off. Here

the RUL is dependent on two operational variables,

x

1

and x

2

, but there will typically be more dimen-

sions in a real situation.

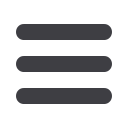

In subsea oil and gas production, many important

variables are not measured due to lack of relia-

ble qualified sensors. Some of these variables are,

however, essential for process control, monitor-

ing and safety, and may further be used to plan

interventions. State and parameter estimation are

powerful tools to obtain estimates of unmeasured

variables and for improving the accuracy of meas-

urements from inaccurate sensors.

In this project, we want to develop models for sub-

sea processes, such as oil-water-gas separation.

These models would form the basis for estimation

of variables, such as oil concentration in water

outlet of the separator. For estimation, we will

use state-of-the-art estimation methods, such as

moving horizon estimation, Bayesian estimation,

extended Kalman filtering etc. Estimation algo-

rithms, if needed, would be tweaked to cater for

specific applications, such as online estimation

and control.

Estimation of un-measurable variables

Project manager and PhD

supervisor, Associate

Prof. Johannes Jäschke

PhD student, Tamal Das

Figure 17:The measurements and the inputs to the

plant are used in the estimation block to estimate

unmeasured process variables

Subsea process

© 2015 Aker Solutions

Inputs

Measure-

ments

Estimator /

Model

(Twin plant)

Estimates

Controller / Operator

(making decisions)

Disturbances