18

SUBPRO Subsea Production and Processing

separation concepts and ideas worth pursuing will

be performed. There are two concepts analysed

previously at NTNU that might be looked into:

separation in spiral conduit and separation in an

inclined pipe using distributed tapping.

At a later stage, the research will select the

most promising concept to develop further (in

agreement with the industrial partners) and

will perform experimental measurements and

numerical simulations to determine separation

performance.

Status:

The project will start mid-2016, due to

limited availability of qualified PhD candidates in

the first announcement round.

The originally proposed work plan has been

revised, considering the delay. The laboratory

facilities have been planned and prepared at the

end of 2015.

The main objective of this project is to perform an

experimental and numerical evaluation of primary

separation techniques for oil and water flows

with potential for subsea implementation. The

techniques to be analysed should be robust, effec-

tive and have low energy requirements.

At an early stage, the research will perform a

systematic evaluation of existing systems and

methods for subsea separation using input from

existing projects and from industrial partners.

Afterwards a screening and pre-evaluation of new

Compact separation concepts

Project manager and main

PhD supervisor, Associate

Prof. Milan Stanko

PhD candidate, hiring in

process

Co-supervisor,

Prof. Sigbjørn Sangesland

Co-supervisor, Prof.

Emeritus Michael Golan

change in operating conditions of one well,

affects all other wells in the cluster and

consequently the total network outcome. The

results of this interdependency is that the

production rate of the integrated system is,

most often, considerably sub-optimal.

This project explores new facilities and system

configurations, as well as novel strategies to

achieve efficient and optimal management of th

optimization over the entire lif of the field, acco

in production conditions associated with the rese

In short, the challenge in the project is to optimis

asset by managing the interdepend ncies betwe

The project will identify and evaluate the feasibili

subsea systems architecture alternatives. A centr

development of a modular and multi-functional

well streams and a quick and easy deployment of

capabilities to a single well, to a group of wells or

named Subsea gate box will be configured to acc

modern subsea process equipment, including; co

deployment and integration in the entire system

The Subsea gate box is configurable as a templat

well modul s a d compartments, containing pro

process equipment may include separators, pum

or flow meters, according to the characteristics o

phase of the project (

Figure 4

) will be to identify

market that suits best to a compact and modular

will include a description of the state-of-the-art s

feasibility analysis of the Subsea gate box and pe

designed for both conventional and low-energy o

Co-supervisor,

Professor Emeritus

Michael Golan

Co-supervisor,

Assoc. Professor

Milan Stanko

Postdoc,

Jesús De Andrade

Postdoc,

Mariana Diaz

Prof. Sigbjørn

Sangesland

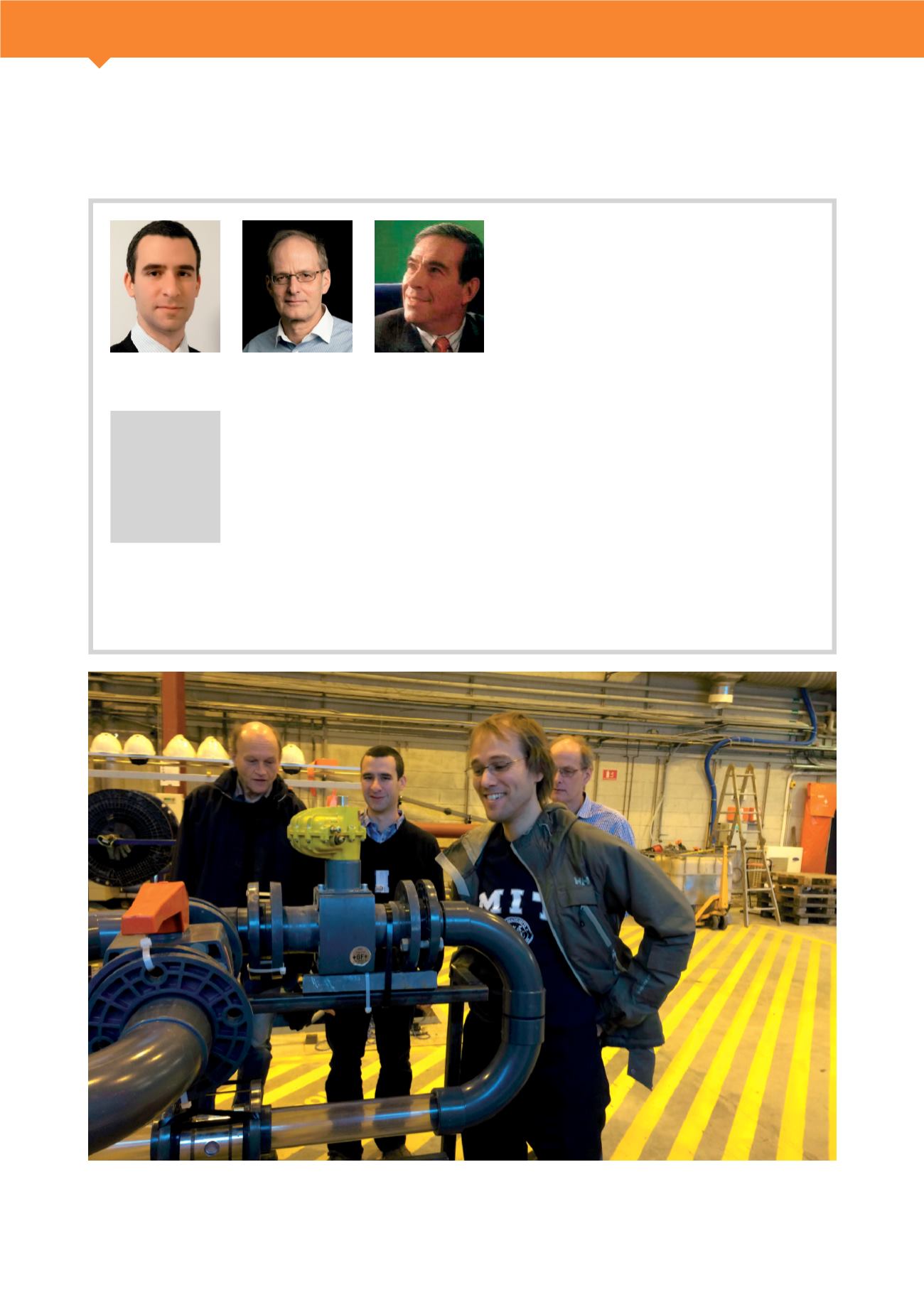

Separator rig, NTNU.