13

Annual Report 2015

Controlled separation of gas, oil and water, efficient treatment and handling of the

produced water and reliable transport of the hydrocarbons are central areas in sub-

sea processing. In order to optimise these processes, proper fluid characterization

and fundamental understanding of the underlying phenomena, like flocculation,

coalescence, precipitation, sedimentation and creaming, is required. The overall

goal is to develop new methods for advanced fluid characterization at conditions

relevant for subsea processing. During the first three years of SUBPRO, the focus

is on developing:

• methods for studying oil drop and gas bubble coalescence at elevated

temperature and pressure in order to facilitate design of subsea water treatment systems

• experimental and simulation methods for predicting build-up and ageing of wax deposits

• sequential separation as an approach for investigating the quality of the oil and water phases at different separation stages

• a new coalescence model

SEPARATION – FLUID CHARACTERIZATION

Research area manager,

Prof. Johan Sjöblom

Research area co-manager, Prof. Gisle Øye

Produced water quality and injectivity

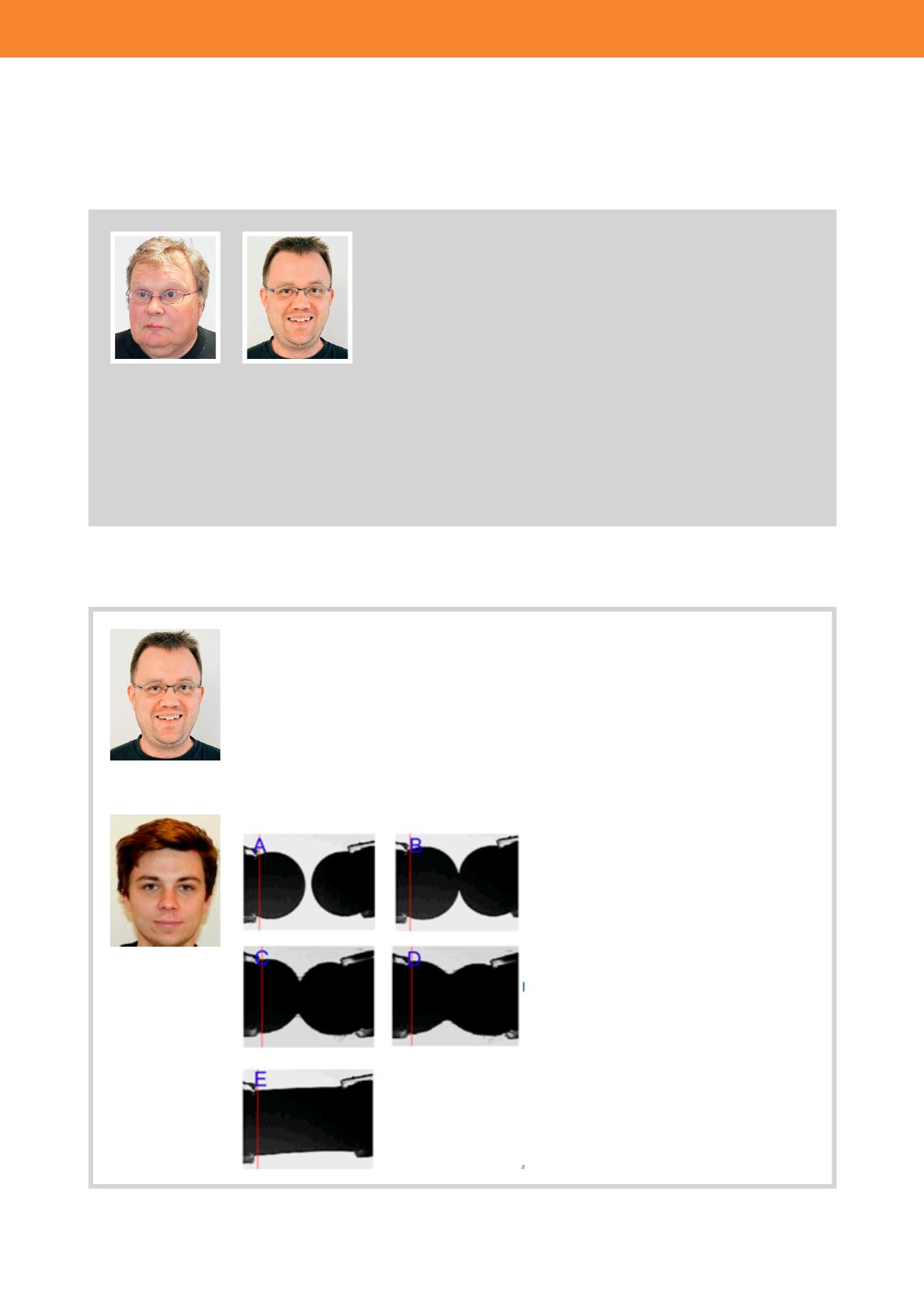

Project manager and PhD

supervisor Prof. Gisle Øye

A major challenge during subsea processing

is treatment of produced water. Dispersed oil

and solids must be separated from the water so

that it reaches sufficient quality to be reinjected

into reservoirs or eventually discharged to sea.

Merging (coalescence) between oil drops or

between oil drops and gas bubbles is a central

phenomenon that will promote the separation.

In this project, the objective is to study how the

chemical composition of crude oil and water influ-

ence the route to drop-drop and drop-bubble coa-

lescence (see Figure 11) at elevated pressure and

temperature. A new microfluidic setup is built for

this purpose. The fundamental knowledge of the

produced water fluids gained in the project can be

applied in design of subsea water treatment sys-

tems for reliable water management. The project

will be carried out in close collaboration with Aker

Solutions, ENGIE, Lundin Norway and Statoil.

PhD student,

Marcin Dudek

Figure 11. The route to coalescence between two oil

drops (determined by a drop-bubble micropipette

setup)

A) Drops approaching

B) Thinning of the aqueous film between the drops

C) Breakage of the thin film

D) Merging of drops

E) Completely merged drops