14

SUBPRO Subsea Production and Processing

Sequential separation

The main topic to be studied in the sequential

separation subproject is the quality of the water

and oil phases from several separation stages,

with a focus on the water quality. Adding additional

subsea oil polishing steps as described in the “All

subsea” and “Subsea Factory” visions entails a

more complex separation system for both phases.

The composition and properties of the well stream

Project manager and PhD

supervisor, Prof. Johan

Sjöblom

PhD candidate,

Are Bertheussen

will change over the lifetime of the installation,

which also affects the water and oil quality at

different separation stages. To predict how inlet

conditions will affect the oil and water quality

at the different stages of the separation, more

knowledge is needed about the compounds that

affect the separation. The compounds of interest

in this subproject are the indigenous polar crude

oil compounds which display surface active prop-

erties, focusing on the resin fraction. This mostly

entails acidic molecules like naphthenic acids or

basic molecules like pyridines. These compounds

partition themselves between the oil and water

and affect the emulsion stability by adsorbing at

the oil-water interface. We will study the partition-

ing kinetics of acids and bases of different sizes,

and how parameters like pH and water cut affect

the partitioning.

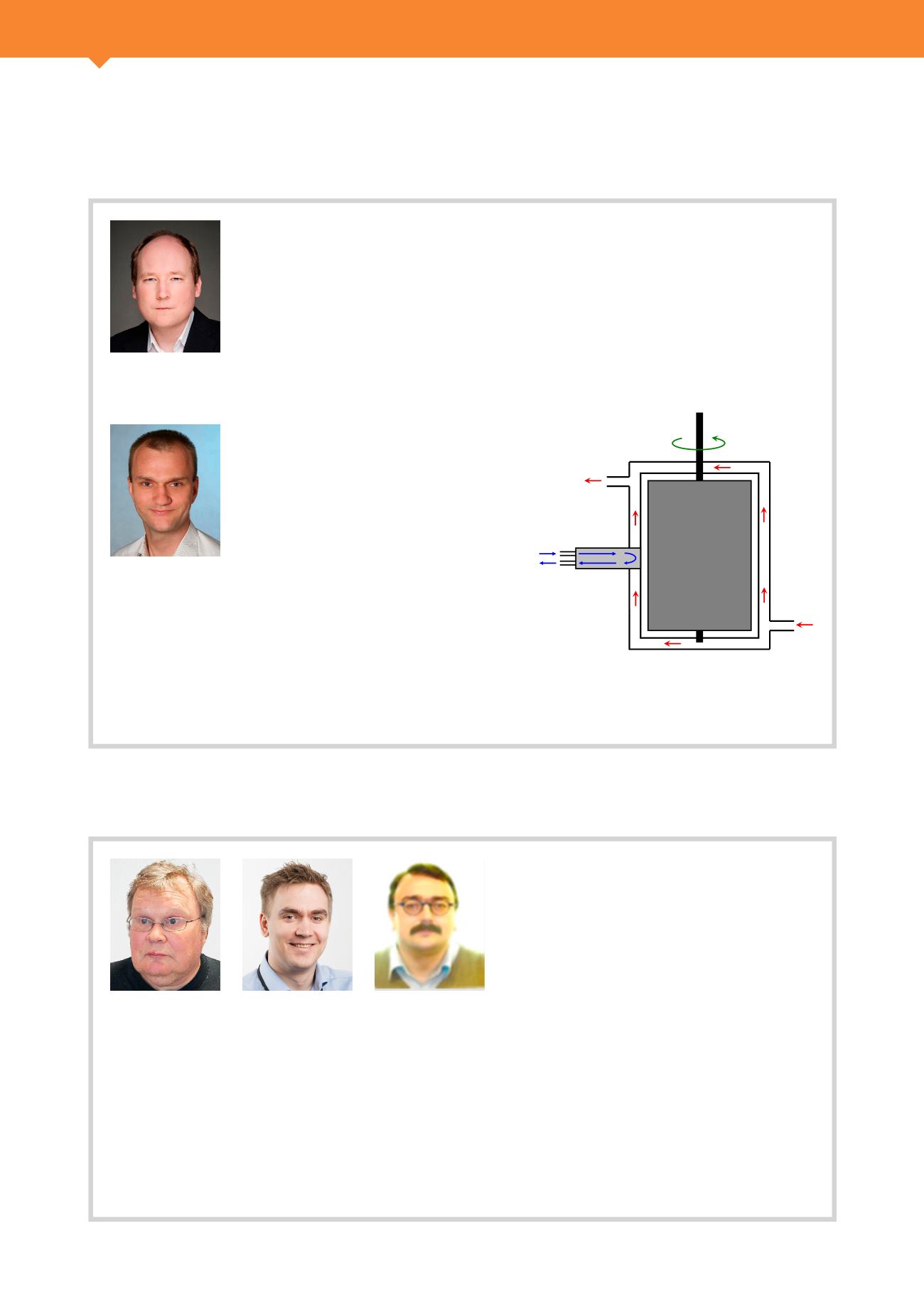

device will be used which matches the shear rate

conditions present in the sub-sea production

system. Figure 12 shows a cartoon of the cold

finger device, which provides improved matching

of heat transfer, mass transfer and momentum

transfer conditions in comparison to traditional

cold finger designs. The development of the wax

deposition simulator will be informed by the

experimental wax deposition measurements.

Paraffin wax deposition may occur in subsea

production systems. Paraffin wax deposition

occurs because of wax crystal precipitation as

waxy crude oil is cooled during pipeline trans-

portation and subsea processing. When warm

waxy crude oil flows past a cold surface, thermal

gradients drive deposition of paraffin wax on the

cold surface. Build-up of wax deposits in a pipe-

line results in reduced cross-sectional flow area

in the pipeline, restricting fluid flow. At extended

tie-back distances, wax deposition may become

a more severe problem due to greater thermal

losses.

A new simulation model is under development to

provide improved forecasts of wax deposition rates

applicable to extended tie-backs and sub-sea

processing units where the bulk fluid temperature

drops below the wax appearance temperature

(WAT). The simulator will predict the build-up of

wax deposits as well as aging of wax deposits. The

simulator will provide predictions for untreated

fluids as well as fluids treated with polymeric wax

inhibitors.

A cold finger apparatus is used to experimentally

measure wax deposition rates. A cold finger

Modelling of wax deposition

Project manager and PhD

supervisor, Associate

Prof. Kristofer Paso

PhD candidate, Jost

Ruwold

Figure 12. The coldfinger apparatus, with cold and

hot water flows labelled with blue and red arrows.

Researcher, Dr. Sebastien

Charles Simon